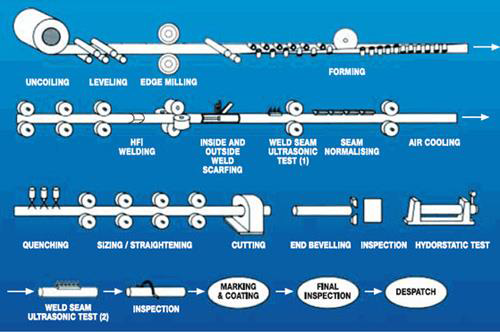

The Tube forming and welding mill is the main processing unit for precision tubes. The raw material at the tube forming stage is a long belt of mild steel strips slit as per required dimension. This strip after passing through forming rollers becomes cylindrical and has an open seam. The seams are then welded by a high frequency induction process after which the tubes are cut as per specifications. The entire process is a non stop online process. ERW tubes are manufactured to withstand various processing strains such as bending, twisting, swagging, total flattening, flaring, bulging and other mechanical operations. Excellent surface finish quality aids plating or painting with minimum surface preparations.

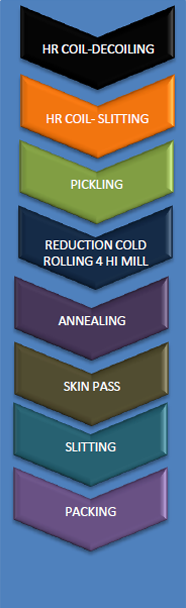

The Cold rolling process starts from Hot Rolled coils being pickled in the acid tank, cold rolling for getting customer required thickness, then annealing for better mechanical properties as per customer's requirement, slitting to exact size of customer's width, packing and dispatch.